Top highly skilled 6G and 6GR Welders Hire from Pakistan

Introduction

The global demand for highly skilled welders, particularly those certified in 6G and 6GR welding, has been on a steady rise. These welders are essential in industries such as oil and gas, construction, shipbuilding, and more. For companies looking to hire top-tier welding professionals from Pakistan, Sony Manpower stands out as the premier recruitment agency. With a proven track record and a commitment to excellence, Sony Manpower provides the best welder recruiting services to meet the needs of international employers.

Why 6G and 6GR Welders Are in High Demand

What Are 6G and 6GR Welding Certifications?

6G and 6GR are among the most advanced welding certifications, requiring welders to demonstrate their ability to weld in all positions (vertical, horizontal, overhead, and flat) on pipes. These certifications are crucial for projects that involve complex and high-stakes welding tasks.

Understanding 6G and 6GR Welding Certifications

What is 6G Welding?

The 6G welding certification is a highly respected and challenging qualification that signifies a welder’s ability to weld pipes in a fixed position at a 45-degree angle. The “6G” designation refers to the complexity and versatility required to execute this type of weld. In the 6G position, the pipe is stationary, and the welder must perform the weld in multiple positions around the pipe, including horizontal, vertical, and overhead positions.

Why is 6G Welding Challenging?

The 6G position is considered one of the most difficult welding tests for several reasons:

- Multiple Welding Positions: Welders must adapt to various positions as they move around the pipe, requiring proficiency in horizontal, vertical, and overhead welding techniques.

- Fixed Position: The pipe remains in a fixed position, meaning the welder must maneuver around it, maintaining consistent quality and technique throughout the weld.

- Access and Visibility: Limited access and visibility can make it difficult to achieve uniform welds, particularly in tight or awkward spaces.

- Gravity and Weld Pool Control: Managing the molten weld pool and gravity’s effects in different orientations demands high skill and precise control.

Applications of 6G Welding

6G certified welders are in high demand for various applications, including:

- Pipeline Construction: Ensuring the integrity and reliability of pipelines transporting oil, gas, and other fluids.

- Power Plants: Welding critical components in nuclear, thermal, and hydroelectric power plants.

- Shipbuilding: Constructing and repairing ships, submarines, and offshore platforms.

- Aerospace: Fabricating and maintaining aircraft and spacecraft components.

What is 6GR Welding?

The 6GR welding certification is an advanced version of the 6G certification. It involves welding around a ring or restriction, which simulates real-world constraints welders might face. The “GR” stands for “groove restricted,” indicating that the weld area is partially obstructed by a ring or other fixture, adding to the complexity of the task.

Why is 6GR Welding More Challenging?

6GR welding is even more demanding than 6G welding due to several factors:

- Restricted Access: The presence of a ring or other obstruction limits the welder’s access to the weld joint, making it harder to position the welding torch and achieve consistent welds.

- Complex Weld Geometry: Navigating around the restriction requires precise control and technique to ensure uniform weld quality.

- Critical Applications: 6GR welding is typically required for critical tasks where weld integrity is paramount, such as in the oil and gas industry.

- Advanced Skills: Welders must demonstrate advanced skills in managing the weld pool, maintaining weld quality, and adapting to restricted access scenarios.

Applications of 6GR Welding

6GR certified welders are essential for highly critical applications, including:

- Oil and Gas Industry: Welding high-pressure pipelines, refineries, and offshore drilling platforms.

- Structural Steel: Constructing and maintaining heavy-duty structures like bridges, towers, and industrial facilities.

- Nuclear Industry: Welding critical components in nuclear reactors and containment vessels.

- Aerospace and Defense: Fabricating and repairing aircraft, spacecraft, and military vehicles.

Sony Manpower: Your Trusted Partner for Hiring Welders

Sony Manpower is a leading recruitment agency in Pakistan, specializing in sourcing and placing highly skilled professionals in international markets. With years of experience and a deep understanding of industry needs, Sony Manpower has built a reputation for excellence and reliability.

Why Choose Sony Manpower?

- Extensive Database: Sony Manpower has a vast database of certified 6G and 6GR welders. Ensuring that clients have access to the best talent available.

- Rigorous Screening Process: All candidates undergo a thorough screening process, including skill assessments, certifications verification, and background checks, to ensure they meet the highest industry standards.

- Tailored Recruitment Solutions: Sony Manpower offers customized recruitment solutions to meet the specific needs of each client, whether they require welders for short-term projects or long-term employment.

- Global Reach: With strong connections to employers in Europe, Canada, the Gulf region, and beyond, Sony Manpower can facilitate international placements with ease.

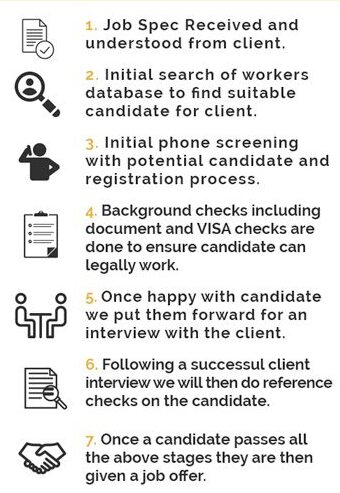

The Recruitment Process

Step 1: Understanding Client Needs

The process begins with a detailed consultation to understand the client’s specific requirements. Including the type of welding projects, the number of welders needed, and any additional skills or certifications required.

Step 2: Candidate Sourcing

Sony Manpower utilizes its extensive network and database to identify potential candidates who meet the client’s criteria. This includes sourcing welders with relevant 6G and 6GR certifications and experience in the specific industry.

Step 3: Screening and Assessment

Candidates undergo a rigorous screening process, which includes:

- Skill Assessments: Practical tests to evaluate the candidate’s welding abilities in various positions.

- Certifications Verification: Ensuring that all candidates hold valid 6G and 6GR certifications.

- Background Checks: Comprehensive checks to verify work history, references, and any other relevant information.

Step 4: Interview and Selection

Qualified candidates are presented to the client for interviews. Sony Manpower assists in coordinating the interview process, providing support and guidance to both the client and the candidates.

Step 5: Hiring and Onboarding

Once the client selects the preferred candidates. Sony Manpower facilitates the hiring process, including contract negotiations, visa processing, and travel arrangements. The agency also provides support during the onboarding process to ensure a smooth transition.

Final Thoughts

Hiring highly skilled 6G and 6GR welders is crucial for the success of many industrial projects. For companies looking to source the best talent from Pakistan, Sony Manpower offers unparalleled expertise and a proven track record. With their extensive database, rigorous screening process, and tailored recruitment solutions. Sony Manpower ensures that clients receive the highest quality manpower to meet their project needs.

If you require top-tier 6G and 6GR welders. contact Sony Manpower today to discover how they can help you find the perfect candidates for your projects.

More Resources:

Best Recruitment Agency In Pakistan for Saudi Arabia

Best Recruitment Agency In Pakistan For Dubai

Top Recruitment Agency In Pakistan For Saudi Arabia